| Availability: | |

|---|---|

| Quantity: | |

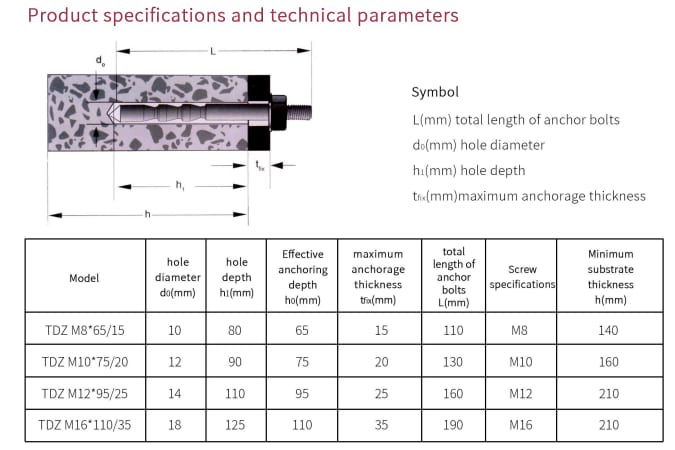

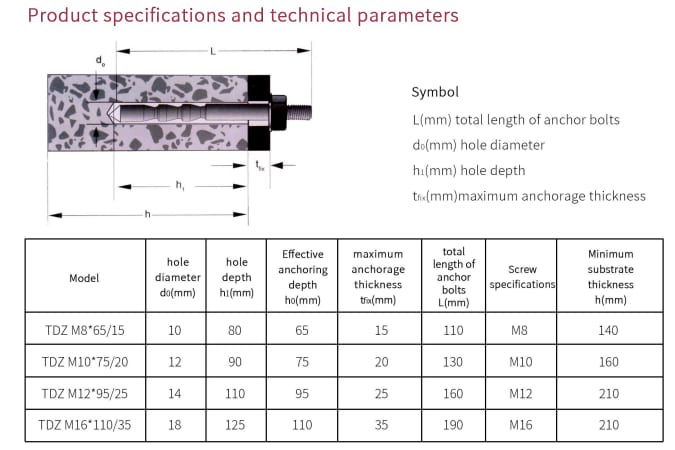

The Tipped Inverted Cone is a specialized chemical anchor bolt designed for high-strength anchoring needs. Its unique inverted cone-shaped head enables strong mechanical interlocking with concrete substrates post-installation, enhancing force transfer during tensile or shear loads. Constructed from premium materials—including 5.8 grade carbon steel, 304 stainless steel, 316 stainless steel, and some variants with galvanizing treatment—this anchor bolt excels in harsh environments, making it suitable for rail transit, high-rise buildings, and skylight engineering.

The Tipped Inverted Cone delivers exceptional High Load-Bearing Capacity through the synergy of Chemical Bonding and Mechanical Locking. This dual mechanism allows it to withstand large tensile forces and shear forces, meeting the demands of high-strength projects such as heavy-duty machinery installation, bridge construction, and high-rise building reinforcement.

With premium materials and optional galvanizing treatment, the Tipped Inverted Cone offers robust Corrosion Resistance. It resists erosion from moisture, chemicals, and outdoor elements, ensuring long-term performance in exposed or harsh environments (e.g., subway tunnels, rooftop skylights). This resistance significantly extends the product’s service life, reducing replacement costs.

The Tipped Inverted Cone exhibits outstanding Seismic Performance under dynamic loads like earthquakes. Its inverted cone design and high-strength bonding maintain the connection integrity with concrete substrates, preventing anchorage failure. It is ideal for seismic brackets and equipment fixation in earthquake-prone regions, enhancing structural safety.

Installation of the Tipped Inverted Cone is user-friendly, involving four core steps: drilling, hole cleaning, glue injection, and screwing in the anchor bolt. No complex equipment or specialized skills are required, which shortens the construction period and lowers labor costs—critical for time-sensitive projects like rail transit upgrades.

In Rail Transit (subways and high-speed rails), the Tipped Inverted Cone secures catenary supports and pantograph arms, ensuring stability during high-speed train operations. It also anchors tunnel joint-sealing cover plates and emergency escape platforms, withstanding vibration to maintain safety.

For high-rise buildings and bridges, the anchor bolt fixes steel beams and columns to concrete foundations, reinforcing overall structural stability. It is also used in concrete renovation projects—anchoring new components or repairing structural cracks in aging buildings to restore integrity.

In Skylight Engineering for commercial and high-rise buildings, the Tipped Inverted Cone secures skylight frames and connecting parts. It withstands wind loads and temperature-induced expansion/contraction, while its corrosion resistance ensures durability in exposed rooftop environments.

We provide end-to-end support for the Tipped Inverted Cone:

Inquiry Channel: Customers can request technical data, application case studies, and material samples to verify product suitability.

Customized Material Options: For projects with harsh conditions (e.g., coastal areas), we offer 316 stainless steel variants for enhanced corrosion resistance.

Installation Guidance: Our team provides on-site or remote support to ensure correct glue injection and anchoring, avoiding installation errors.

After-Sales Troubleshooting: We assist with resolving anchoring issues and offer maintenance recommendations to preserve long-term performance.

The Tipped Inverted Cone is a specialized chemical anchor bolt designed for high-strength anchoring needs. Its unique inverted cone-shaped head enables strong mechanical interlocking with concrete substrates post-installation, enhancing force transfer during tensile or shear loads. Constructed from premium materials—including 5.8 grade carbon steel, 304 stainless steel, 316 stainless steel, and some variants with galvanizing treatment—this anchor bolt excels in harsh environments, making it suitable for rail transit, high-rise buildings, and skylight engineering.

The Tipped Inverted Cone delivers exceptional High Load-Bearing Capacity through the synergy of Chemical Bonding and Mechanical Locking. This dual mechanism allows it to withstand large tensile forces and shear forces, meeting the demands of high-strength projects such as heavy-duty machinery installation, bridge construction, and high-rise building reinforcement.

With premium materials and optional galvanizing treatment, the Tipped Inverted Cone offers robust Corrosion Resistance. It resists erosion from moisture, chemicals, and outdoor elements, ensuring long-term performance in exposed or harsh environments (e.g., subway tunnels, rooftop skylights). This resistance significantly extends the product’s service life, reducing replacement costs.

The Tipped Inverted Cone exhibits outstanding Seismic Performance under dynamic loads like earthquakes. Its inverted cone design and high-strength bonding maintain the connection integrity with concrete substrates, preventing anchorage failure. It is ideal for seismic brackets and equipment fixation in earthquake-prone regions, enhancing structural safety.

Installation of the Tipped Inverted Cone is user-friendly, involving four core steps: drilling, hole cleaning, glue injection, and screwing in the anchor bolt. No complex equipment or specialized skills are required, which shortens the construction period and lowers labor costs—critical for time-sensitive projects like rail transit upgrades.

In Rail Transit (subways and high-speed rails), the Tipped Inverted Cone secures catenary supports and pantograph arms, ensuring stability during high-speed train operations. It also anchors tunnel joint-sealing cover plates and emergency escape platforms, withstanding vibration to maintain safety.

For high-rise buildings and bridges, the anchor bolt fixes steel beams and columns to concrete foundations, reinforcing overall structural stability. It is also used in concrete renovation projects—anchoring new components or repairing structural cracks in aging buildings to restore integrity.

In Skylight Engineering for commercial and high-rise buildings, the Tipped Inverted Cone secures skylight frames and connecting parts. It withstands wind loads and temperature-induced expansion/contraction, while its corrosion resistance ensures durability in exposed rooftop environments.

We provide end-to-end support for the Tipped Inverted Cone:

Inquiry Channel: Customers can request technical data, application case studies, and material samples to verify product suitability.

Customized Material Options: For projects with harsh conditions (e.g., coastal areas), we offer 316 stainless steel variants for enhanced corrosion resistance.

Installation Guidance: Our team provides on-site or remote support to ensure correct glue injection and anchoring, avoiding installation errors.

After-Sales Troubleshooting: We assist with resolving anchoring issues and offer maintenance recommendations to preserve long-term performance.